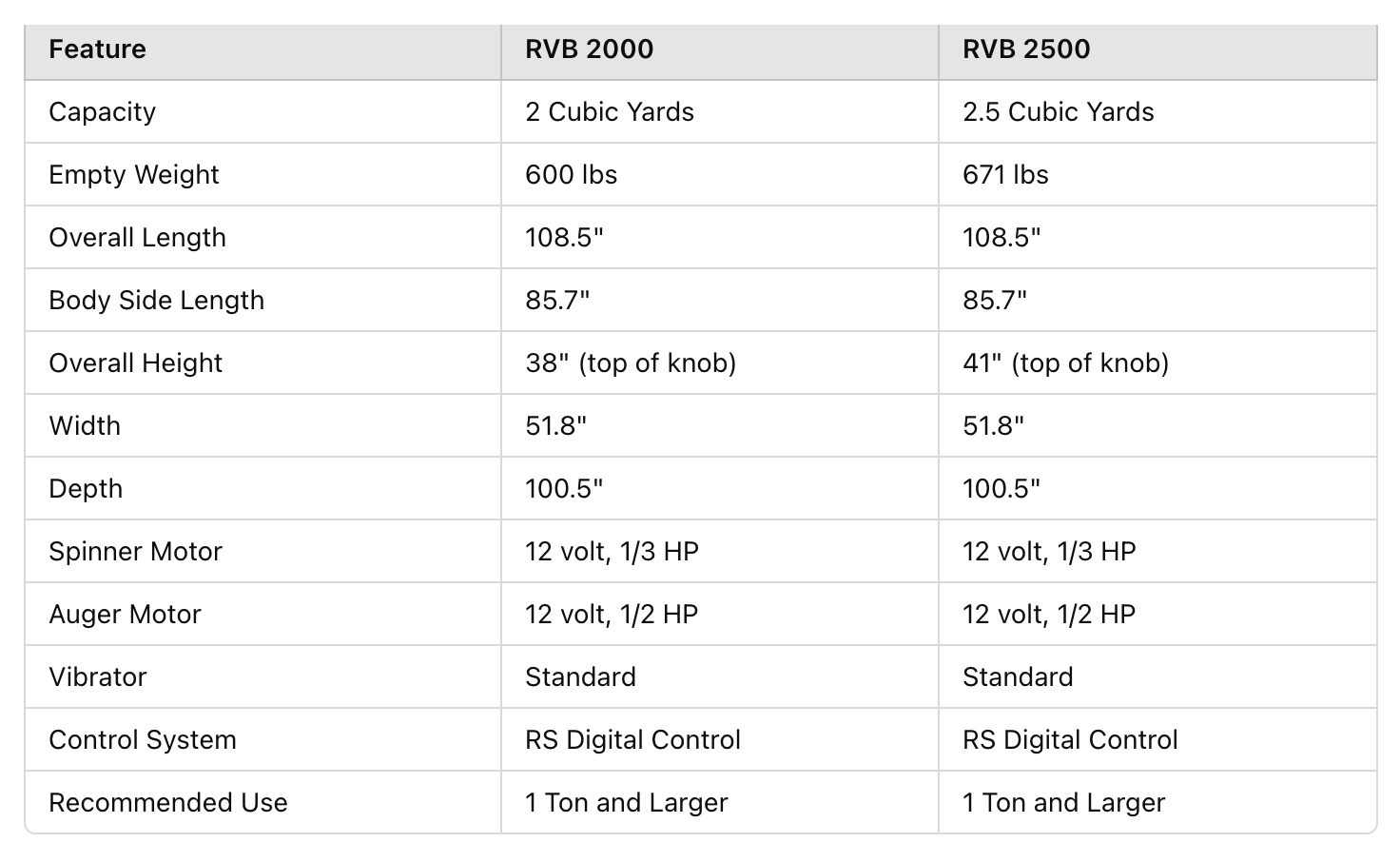

Sno-Way is making it easier for snow and ice removal professionals with the launch of two new stainless steel V-Box spreaders: the RVBS 2000 and RVBS 2500. Built for durability and efficiency, these spreaders feature heavy-duty stainless steel hoppers, superior spread control, and user-friendly smart controls, ensuring reliable performance even in the harshest conditions. Designed to maximize material flow and reduce waste, Sno-Way’s latest innovations are tailored for those who demand precision and productivity in every snowfall.

Winter weather brings snow and ice, creating challenges for both residential and commercial snow removal. Sno-Way, a leader in snow and ice management solutions, has expanded its RVB spreader lineup by introducing two new stainless steel V-Box spreaders: the RVBS 2000 and RVBS 2500. Designed for professional snow and ice removal specialists, these spreaders combine durability, precision, and efficiency to tackle even the harshest winter conditions.

Why Choose Stainless Steel V-Box Spreaders?

These spreaders are built with a heavy-duty stainless steel hopper mounted on a custom stainless steel frame, ensuring longevity and resistance to rust and corrosion. Whether you’re clearing parking lots or large driveways, these spreaders provide reliable performance season after season.

Key Features at a Glance:

Durable Build:

- Stainless steel hopper and frame for superior rust resistance.

- Designed to withstand harsh winter conditions.

Superior Spread Pattern:

- 16″ four-flute poly spinner ensures an even spread pattern up to 30 feet.

- Industry-leading spread control for precise material distribution.

Powerful Performance:

- RVBS 2000 and 2500 models feature a 1/2 HP direct-drive gearbox for the auger and a 1/3 HP motor for the spinner.

- Fully enclosed motors protect against salt and water penetration.

Efficient Material Flow:

- Specially designed hopper walls maximize the flow of tough materials, reducing clogging and material bridging.

User-Friendly Operation:

- One simple harness connects the power supply with a water-tight Deutsch connector.

- Plug-and-play harness eliminates the need for cutting or splicing wires.

- Adjustable inverted vee system adapts to different spreading materials, allowing precise control over the material amount delivered to the auger.

Smart Controls:

- RS Digital Control System:

- Simple buttons and controls that are easy to use and understand.

- Independent auger and spinner speed adjustments.

- Push buttons to turn the spreader on/off, auxiliary light (optional), wetting system (optional), vibrator, and pause functions.

- Auto Mode manages all functions automatically.

- Well-lit LCD screen with auger and spinner graph display.

- Reversing function for clearing jams.

Optional Enhancements:

Salt Wetting System:

Want more information on this?