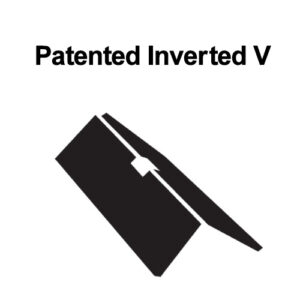

Welcome to Snow Plow News, your go-to source for all things related to snow removal equipment and technology. In today’s feature, we delve into the groundbreaking advancements made by a leading spreader manufacturer, as they introduce a cutting-edge solution for flowing multiple materials in a single unit. This game-changing technology, which combines a patented inverted-V system and an intelligent control system, promises to revolutionize material flow in spreaders.

July, 6 2023 | Staff Editor

“Inverted Vee: Redefining Material Flow”

“Inverted Vee: Redefining Material Flow”

According to Terry Wendorff, President of Sno-Way International, in our exclusive interview, one of the first challenges addressed by the manufacturer was the need to flow different materials efficiently. To tackle this obstacle, they developed a patented Inverted Vee system. This innovative design allows operators to adjust the flow characteristics of the materials being spread. When dealing with quick-flowing materials, the Inverted Vee is closed, whereas for substances with poor flow properties, such as wet sand, the Inverted Vee is opened, allowing for the removal of specific sections.

Balancing Power and Speed

The use of electric motors in spreaders presents a unique challenge in terms of power management. The manufacturer understood this dilemma and strived to strike the perfect balance between power and speed. By optimizing this delicate relationship, they ensured that operators could achieve the desired output without exceeding the electric motor’s capacity. The result is an efficient material flow system that maximizes performance while remaining within the limitations of the available power.

Intelligent Control System

In addition to the Inverted Vee system, the manufacturer integrated an intelligent control system into their spreaders. This control system can be likened to a cruise control system, as it automatically adjusts the power output based on the operational conditions. For instance, if a large amount of material suddenly drops onto the auger, the control system senses the increased load and boosts the power to maintain smooth movement. Once the material flow returns to its standard rate, the system reduces the power output accordingly. This seamless adjustment eliminates the need for manual intervention, allowing the operator to focus solely on driving the truck.

Unleashing the Operator’s Potential

By combining the Inverted Vee system and the intelligent control system, the manufacturer has created a revolutionary solution that empowers operators while ensuring optimal material flow. The incorporation of these technologies frees up operators from the burdensome task of monitoring and managing material flow. Instead, they can concentrate on operating the truck effectively, confident that the advanced technology will handle the intricacies of material flow on their behalf.

Conclusion

The introduction of the patented Inverted Vee system and the intelligent control system marks a significant milestone in the realm of spreader technology. With the ability to flow various materials efficiently and adapt to changing conditions automatically, snow and ice removal operators worldwide can now achieve optimal performance with minimal effort. As we continue to witness innovation in the snow & ice removal industry, we eagerly await further developments that will enhance the efficiency and effectiveness of spreader equipment. Stay tuned to Snow Plow News for the latest updates on cutting-edge technologies and advancements shaping the future of snow and ice removal.

To Learn More

To discover more about the innovative features and capabilities of the Sno-Way spreaders, visit snoway.com.

Want more information on this?