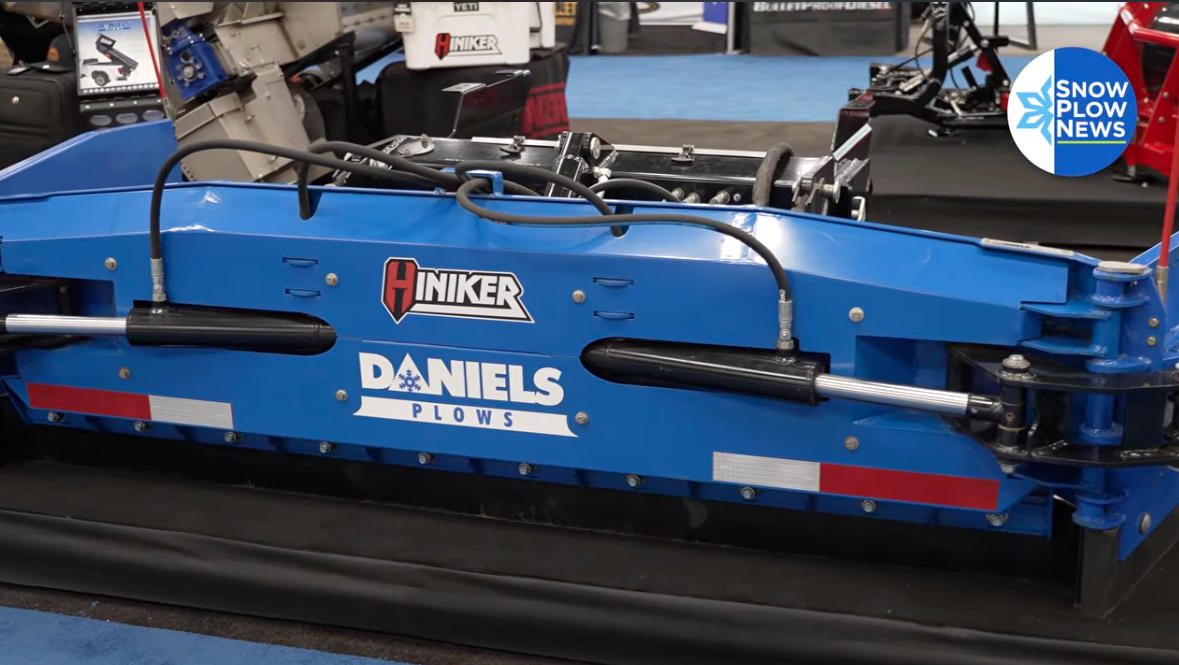

Hiniker Daniels breaks down why back blades are becoming a go-to upgrade for snow contractors. With better scraping, wider passes, and safer visibility, rear-mounted plows are proving to be one of the biggest productivity boosts heading into 2026.

In recent years, the snow and ice industry has seen a surge of interest in rear-mounted back blades, a trend many contractors once questioned but now swear by. To understand what’s driving the shift, Snow Plow News sat down with Wade Madsen of Hiniker Daniels, who broke down the engineering logic, productivity impact, and real-world advantages behind back-blade adoption.

Why Put a Plow on the Back of the Truck?

It’s one of the most common questions contractors ask:

Why mount a plow on the back and why drive over the snow before you plow it?

According to Madsen, the answer starts with the physics of equipment itself.

“Trucks and all equipment are made for pulling, not pushing,”

—Wade Madsen, Hiniker Daniels

When a back blade applies down pressure, it scrapes directly to pavement with far greater consistency than most front-only setups. Because the operator is moving forward, not backward, the driver has full visibility of their surroundings, not just mirrors and blind spots. The forward-facing operation makes the entire process safer, more controlled, and more efficient.

Better Together: Front + Back Blade Pairing

While back blades can be run alone in certain situations, most contractors see the biggest advantage when front and rear plows work together.

The hydraulic wing back blade creates a wide, controlled path, while the front blade supports clearing and cleanup. This dual setup dramatically improves the flow of snow and reduces time spent revisiting the same area.

Up to 16 Feet of Clearing Width

One of the biggest performance advantages comes from width.

Hydraulic wing back blades can expand out to 16 feet, twice the size of most front plows.

Even a heavy-duty 10-foot front blade drops down to about 8 feet when fully angled. With a back blade, contractors maintain the full clearing width while moving straight forward.

A True Productivity Multiplier

Madsen stated that there is 50%increase in production with the back blade, but he says the real proof is in the behavior of the contractors themselves.

“Anybody who has the pull plow and uses it will never go back,” he says.

“That alone proves the productivity is there.”

Why Back Blades Are Poised for Major Growth in 2026

As contractors look for ways to stay competitive amid rising labor shortages, heavier storms, and customer demands for cleaner surfaces, back blades are emerging as one of the most impactful equipment upgrades on the market.

The ability to:

- clear wider paths

- scrape down to pavement with down pressure

- operate safely while facing forward

- complete more work per hour

- and eliminate the need for additional equipment hauls like skid steers

makes rear-mounted plows an increasingly logical choice for both small operations and large-scale commercial fleets.